Stainless hlau 17-7PH

Common Trade Names:17-7PH, SUS 631, UAS17700,07Cr17Ni7Al, W. Nr.1.4568

17-7PH yog austenitic-martensitic nag lossis daus hardening stainless hlau tsim nyob rau hauv lub hauv paus ntawm 18-8CrNi, tseem hu ua tswj theem hloov stainless hlau.Thaum cov tshuaj kho kub, 1900 ° F, cov hlau yog austenitic tab sis undergoes transformation mus rau ib tug tsawg- carbon martensitic qauv thaum lub sij hawm txias rau chav tsev kub.Qhov kev hloov pauv no tsis ua tiav kom txog thaum qhov kub poob mus rau 90 ° F.Tom qab cua sov rau qhov kub ntawm 900-1150 ° F rau ib mus rau plaub teev nag lossis daus ntxiv dag zog rau cov hlau.Qhov kev kho hardening no kuj tempers cov qauv martensitic, nce ductility thiab toughness

| C | Cr | Ni | Si | Mn | P | S | Al |

| ≤ 0.09 | 16.0-18.0 Nws | 6.5-7.75 Nws | ≤1.0 | ≤1.0 | ≤ 0.04 | ≤ 0.03 | 0.75-1.5 hli |

| Qhov ceev (g / cm3) | Melting point (℃) |

| 7.65 ib | 1415-1450 Ib |

| Qhov xwm txheej | IB/N/mm2 | 0.2 / N / mm2 | δ 5/% | ψ | HRW | |

| Kev kho mob | ≤1030 | ≤380 | 20 | - | ≤ 229 | |

| Precipitationhardening | 510 ℃ kev laus | 1230 | 1030 | 4 | 10 | ≥383 |

| 565 ℃ kev laus | 1140 | 960 ua | 5 | 25 | ≥363 | |

17-7PH Standards thiab Specifications

AMS 5604, AMS 5643, AMS 5825, ASME SA 564, ASME SA 693, ASME SA 705, ASME Hom 630, ASTM A 564, ASTM A 693, ASTM A 705, ASTM Hom 630

Condition A - H1150, ISO 15156-3, NACE MR0175, S17400, UNS S17400, W.Nr./EN 1.4548

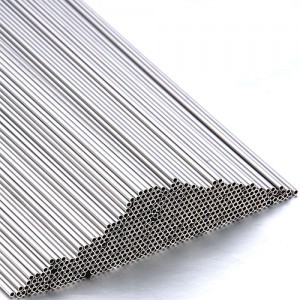

| Bar / Qws | Hlau | Sawb / Coil | Ntawv / phaj | Tube / Tube |

17-7PH Cov khoom muaj nyob rau hauv Sekonic hlau

Vim li cas 17-7 PH?

•Siab tensile zog thiab hardness rau 600 ° F

•Corrosion resistant

•Zoo heev oxidation tsis kam mus txog 1100 ° F

•Creep-rupture zog rau 900 ° F

17-7 PHAB:

•Rooj vag li qub

•Cov khoom siv tshuaj ua haujlwm

•Pump shafts, iav, plungers

•Valve stems, pob, bushings, rooj zaum

•Fasteners