High Temperautre Spring Disc Caij nplooj ntoos hlav Wave Spring

Kub kub caij nplooj ntoos hlav:

Caij nplooj ntoos hlav yog ib qho khoom siv uas siv elasticity los ua haujlwm.Cov khoom ua los ntawm cov ntaub ntawv elastic deform nyob rau hauv qhov kev txiav txim ntawm sab nraud quab yuam, thiab rov qab mus rau lawv cov qub zoo tom qab tshem tawm lub zog sab nraud.Kuj tseem siv tau ua "caij nplooj ntoos hlav".Feem ntau ua los ntawm caij nplooj ntoos hlav steel.Hom springs yog complex thiab ntau haiv neeg.

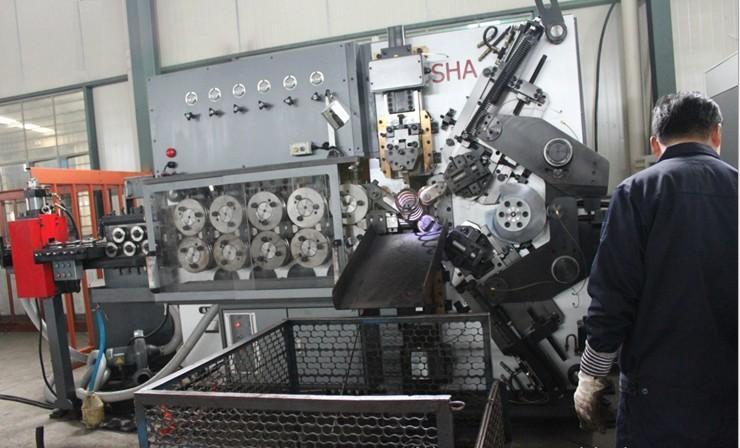

Peb Lub Tuam Txhab United Nrog professonial Spring Factories Main Tsim thiab muab Cov Kub Kub Springs

• Cov khoom siv caij nplooj ntoos hlav kub:

SUS 304,SUS 316, SUS631/17-7PH, SUS632/15-7Mo50CrVA, 30W4Cr2VA,

Inconel X-750, ib 718, Nimonic 90, Incoloy A286 (SUH660)

• Hom caij nplooj ntoos hlav:

→ Compression Springs → Extension caij nplooj ntoos hlav

→ Torsion Spring → Bending caij nplooj ntoos hlav

♦ Wave Spring ♦ ScrollCaij nplooj ntoos hlav♦ Disc Spring

♦ Lub Nplhaib Caij Nplooj Hlav ♦ Lub Caij Nplooj Ntoos Hlav Tshwj Xeeb, thiab lwm yam

| Hom khoom | Khoom npe | Qhov siab tshaj plaws thov kub°C |

| stainless hlau | SUS304/SUS316 | 200 |

| SUS631/17-7PH | 370 | |

| SUS632/15-7Mo | 470 ib | |

| Alloy caij nplooj ntoos hlav steel | 50 CrVA | 300 |

| 30W4Cr2VA | 500 | |

| Kub kub nickel puag alloy | Incoloy A286 (GH2132) | 600 |

| Inconel X-750 (GH4145) | 600 | |

| Tom ntej: Inconel 718 (GH4169) | 690 ib | |

| Nimonic 90 (GH4090) | 800 (γ<0.2) | |

| hwv 4099 | 1000 (γ<0.1) |

♦♦♦ Disc Springs♦♦♦

Lawv yog siv nyob rau hauv li qub, flanges, clutches, brakes, torque converters, High-voltage hloov, bolt zawm, pipeline kev them nyiaj yug, shockproof thiab shockproof teb.Lawv ua raws li DIN EN16983 (DIN2093).

Sab nraud txoj kab uas hla yog li ntawm 6mm mus rau 1000mm.

Cov ntaub ntawv muaj xws lialloy steel 51CrV4, carbon steel SK85, 1074;

• Stainless hlau ASTM301, 304, 316, 17-7PH, 17-4PH, 15-7Mo;

• Thaum tshav kub kub-resistant steel H13, X30WCrV53, X22CrMoV12-1, X39CrMo17-1;

• Kub kub resistant stainless hlau Inconel X750, Inconel X718, Nimonic 90, thiab lwm yam.

♦♦♦ Wave Springs♦♦♦

Wave caij nplooj ntoos hlav yog ib lub nplhaib-zoo li tus elastic hlau uas muaj li ntawm ob peb yoj crests thiab hav.Wave springs yog dav siv nyob rau hauv motors, textile machinery, hydraulic khoom, tsheb thiab lwm yam lag luam.Lub ntsiab installation thiab specifications (nominal size) ntawm chav bearing yog haum.Los yog hauv lub qhov, qhov chaw teeb tsa me me, thiab nws muaj qhov tshwj xeeb ntawm kev txo suab nrov thiab txo kev co.

Sab nraud txoj kab uas hla yog li ntawm 6mm mus rau 1000mm.Lub thickness ntawm 0.4mm mus rau 5.0mm.

Kev tiv thaiv xeb

- Phosphating

- Mechanical galvanizing

- Nickel plated

- Jiaomei

Lawv muaj cov yam ntxwv ntawm me me deformation thiab loj load.Nws kuj muaj cov yam ntxwv hauv qab no.

- Disc springs tuaj yeem tau txais cov yam ntxwv sib txawv los ntawm kev sib txawv ntawm kev sib hloov thiab sib tshooj.

- Piv nrog rau lwm cov springs, disc springs siv qhov chaw tsawg dua.

- Thaum siv ntau daim ntawv sib xyaw ua ke, cov nyhuv damping yog nce.

- Thaum siv tsim nyog, nws yuav tsis deform lossis tawg.

- Lub neej qaug zog ntev dua.

| Cov khoom siv caij nplooj ntoos hlav | Ua haujlwm Temp | Tensile zog | Elastic Modulus KN//mm2 | Chemistry% | ||||||||||||||||||

| °C | N / hli 2 | RT ° C | 100 ° C | 200 ° C | 300 ° C | 400 ° C | 500 ° C | 600 ° C | C | Si | Mn | P | S | Cr | Ni | Lwm tus | ||||||

| T8A SK85 | -50 rau +100 | 1200-1800 Nws | 206 | 202 | - | - | - | - | - | 0.80-0.09 Nws | ≤ 0.35 | ≤ 0.50 | ≤ 0.03 | ≤ 0.03 | ≤ 0.20 | ≤ 0.25 | Cu≤0.30 Nws | |||||

| 50 CrV4 SUP10 | -50 txog +200 | 1200-1800 Nws | 206 | 202 | 196 | - | - | - | - | 0.47-0.55 Nws | ≤ 0.4 | 0.7 ua1.1 | ≤ 0.025 | 0.025 ib | 0.9 1.2 ib | ≤ 0.4 | V: 0.1 0.25 NwsMo≤0.1 | |||||

| C75 | -50 rau +100 | 1200-1800 Nws | 206 | 202 | - | - | - | - | - | 0.70-0.80 Nws | 0.15-0.35 dr hab | 0.60 0.90 Nws | ≤ 0.025 | 0.025 ib | ≤ 0.4 | ≤ 0.4 | Mo≤0.1 | |||||

| 60 Si2Mn SUP6 | -50 txog +200 | 1200-1800 Nws | 206 | 202 | 196 | - | - | - | - | 0.56-0.64 Nws | 1.50-2.0 Nws | 0.6 0.9 ib | ≤ 0.035 | 0.035 ib | ≤ 0.35 | ≤ 0.35 | ||||||

| X 10CrNi 18-8 SUS301 | -200 txog +200 | 1150-1500 Nws | 190 | 186 | 180 | - | - | - | - | 0.05-0.15 dr hab | ≤ 2.0 | ≤ 2.0 | ≤ 0.045 | 0.015 ib | 16.0 19.0 Nws | 6.0 9.5 | Mo≤ 0.08 | |||||

| X 5CrNi 18-10SUS304 | -200 txog +200 | 1000-1500 | 185 | 179 | 171 | - | - | - | - | ≤ 0.07 | ≤ 1.0 | ≤ 2.0 | ≤ 0.045 | 0.015 ib | 17.019.5 Nws | 6.0 9.5 | N≤ 0.11 | |||||

| X 5CrNiMo 17-12-2 SUS316 | -200 txog +200 | 1000-1500 | 180 | 176 | 171 | - | - | - | - | ≤ 0.07 | ≤ 1.0 | ≤ 2.0 | ≤ 0.045 | 0.015 ib | 16.5-18.5 Nws | 10.0 13.0 Nws | Mo: 2.0-2.5N≤ 0.11 | |||||

| X 7CrNiAl 17-7 SUS631 | -200 txog +300 | 1150-1700 Nws | 195 | 190 | 180 | 171 | - | - | - | ≤ 0.09 | ≤ 0.7 | ≤ 1.0 | ≤ 0.04 | 0.015 ib | 16.0 18.0 Nws | 6.5 7.8 ib | Al: 0.7-1.5 | |||||

| X5CrNiCuNb 16-4 SUS630 | -200 txog +300 | 1150-1700 Nws | 195 | 190 | 180 | 171 | - | - | - | ≤ 0.07 | ≤ 1.0 | ≤ 1.0 | ≤ 0.035 | 0.03 ib | 15.0 17.0 Nws | 3.0 5.0 Nws | ||||||

| X8CrNiMoAl 15-7-2 | -200 txog +300 | 1150-1700 Nws | 195 | 190 | 180 | 171 | - | - | - | ≤ 0.09 | ≤ 1.0 | ≤ 1.0 | ≤ 0.04 | 0.03 ib | 14.0 16.0 Nws | 6.5 7.75 Nws | Mo:2.0-3.0 NwsAl: 0.75-1.5 | |||||

| Hlau X39CrMo 17-1 | -50 rau +400 | 1200-1400 Nws | 215 | 212 | 205 | 200 | 190 | - | - | 0.33-0.45 dr hab | ≤ 1.0 | ≤ 1.5 | ≤ 0.04 | 0.03 ib | 15.5 17.5 Nws | ≤ 1.0 | Mo: 0.7-1.3 | |||||

| X 22CrMoV 12-1 | -50 rau +500 | 1200-1400 Nws | 216 | 209 | 200 | 190 | 179 | 167 | - | 0.18-0.24 dr hab | ≤ 0.5 | 0.4 0.9 Nws | ≤ 0.025 | 0.015 ib | 11 12.5 Nws | 0.3-0.8 hli | V: 0.25-0.35 NwsMo: 0.8-1.2 | |||||

| X30WCrV53 SKD4 | -50 rau +500 | ≥ 1470 | 216 | 209 | 200 | 190 | 179 | 167 | - | 0.25-0.35 Nws | 0.15-0.30 Nws | 0.20 0.40 Nws | ≤ 0.035 | 0.035 ib | 2.2 2.5 | ≤ 0.35 | V: 0.5-0.7 W: 4-5 | |||||

| X40CrMoV5-1 SKD61 | -150 txog +600 | 1650-1990 Nws | 206 | 200 | 196 | 189 | 186 | 158 | - | 0.32 0.40 Nws | 0.8 1.20 Nws | 0.20 0.50 Nws | ≤ 0.030 | 0.030 Nws | 4.75 5.50 Nws | V: 0.80-1.20Mo: 1.1-75 | ||||||

| Nickel Inconel X750 | -200 txog +600 | ≥ 1170 | 214 | 207 | 198 | 190 | 179 | 170 | 158 | ≤ 0.08 | ≤ 0.50 | ≤ 1.0 | ≤ 0.02 | 0.015 ib | 14.0 17.0 Nws | ≥70 | Co≤ 1.0 Ti2.25-2.75 Fib 5.0-9.0 | |||||

| Inconel X718 | -200 txog +600 | ≥ 1240 | 199 | 195 | 190 | 185 | 179 | 174 | 167 | 0.02 0.08 Nws | ≤ 0.35 | ≤ 0.35 | ≤ 0.015 | 0.015 ib | 17.0 21.0 Nws | 50.0 55.0 Nws | V = 1.0Mo: 0.70-1.15 | |||||

| Nim 90 | -200 txog +700 | ≥1100 | 220 | 216 | 208 | 202 | 193 | 187 | 178 | ≤ 0.13 | ≤ 1.0 | ≤ 1.0 | ≤ 0.03 | 0.015 ib | 18.0 21.0 Nws | Bal | V15.0-21.0Mo: 2.0-3.0 Al≤ 0.2 | |||||

♦♦♦ High Tempeature Spring Materials Features: ♦♦♦

♦ 304 stainless hlau

304 stainless hlau yog deformed los ntawm txias ua hauj lwm los txhim kho nws elastic zog.Nws tsis tuaj yeem hardened los ntawm kev kho cua sov.Nws yuav tsim cov hlau nplaum thaum ua haujlwm txias.304 stainless hlau muaj zog corrosion kuj thiab lub cev zoo.

316 stainless hlau yog deformed los ntawm txias ua hauj lwm los txhim kho nws elastic zog, thiab tsis tuaj yeem hardened los ntawm kev kho cua sov.Nws yuav tsim cov hlau nplaum thaum ua haujlwm txias.316 stainless hlau muaj molybdenum, uas muaj zog corrosion kuj tshaj 304 stainless hlau, thiab tuaj yeem tiv taus corrosion hauv tshuaj siv.

17-7PH zoo ib yam corrosion kuj mus rau 304 stainless hlau, uas tuaj yeem raug precipitated los ntawm kev kho cua sov thiab nag lossis daus hardening.Nws muaj lub zog tensile thiab yield zog.Kev ua haujlwm qaug zog zoo dua li 304 stainless hlau thiab 65Mn carbon hlau.Nws kuj muaj zoo elasticity nyob rau hauv ℃ ib puag ncig.

♦15-7Mo (GH632, 0Cr15Ni7Mo2Al)

15-7MoHas zoo ib yam corrosion kuj rau 316 stainless hlau.Nws tuaj yeem raug precipitated los ntawm kev kho cua sov thiab nag lossis daus hardening.Nws muaj lub zog tensile thiab tawm los, thiab nws txoj kev qaug zog yog zoo dua li 316 stainless hlau thiab 65Mn carbon hlau.Nws kuj muaj zoo elasticity nyob rau hauv ℃ ib puag ncig.

Inconel X-750 yog nickel-based nag lossis daus hardening deformation superalloy.Nws tsuas yog siv r'phase raws li kev laus nag lossis daus hardening theem.Qhov pom zoo kub yog qis dua 540 ℃.Cov hlau muaj qee qhov kev tiv thaiv corrosion thiab oxidation tsis kam, thiab muaj qee yam kev ua haujlwm kub.

♦Tom ntej: Inconel 718 (GH4169)

Inconel 718 yog nickel-based nag lossis daus hardening deformation superalloy.Qhov ntsuas kub tau pom zoo yog -253--600 ℃.Cov hlau muaj lub zog siab hauv qab 600 ° C, muaj kev qaug zog zoo, tiv thaiv hluav taws xob, oxidation tsis kam thiab corrosion kuj, nrog rau kev ua haujlwm zoo thiab kev ruaj ntseg ntev.

Alloy A-286 yog hlau-raws li precipitation hardening deformation siab kub alloy.Qhov pom zoo ua haujlwm kub yog qis dua 540 ℃.Cov hlau muaj qhov kub thiab txias tsis muaj zog thiab ruaj khov mus ntev, zoo corrosion kuj thiab thermal deformation kev ua tau zoo, thiab muaj kev ua tau zoo plasticity thiab txaus siab vuam kev ua tau zoo.