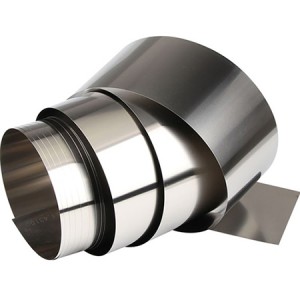

4J29-Kovar alloy sawb Kovar bar/kovar ntawv/kovar raj

Cov npe lag luam: Kovar Alloy, 4J29, UNS K94610 (FeNi29Co17),29HК Kovar, KV-1,29HК-BИ, Werkstoff Nr.1.3981

Qhov no alloy kuj caled iav kaw thiab tswj expansion alloy,Lub alloy muaj alinear expansion coefficientzoo ib yam li silicon boron nyuaj iav ntawm 20-450 ° C, aCurie point siab dua, thiab qhov zoo ntawm qhov kub thiab txias ntawm cov qauv kev ruaj ntseg.Cov oxide zaj duab xis ntawm cov hlau yog tuab thiab tuaj yeem ua tau zooua dejlos ntawmiav.Nws tsis cuam tshuam nrog mercury thiab yog haum rau siv nyob rau hauv mercury-muaj paug meters.Nws yog cov khoom siv sib khi tseem ceeb rau cov khoom siv hluav taws xob lub tshuab nqus tsev.

| C | Cr | Ni | Mo | Si | Mn | P | S | Fe | Co | Cu |

| ≤ 0.03 | ≤0.2 | 28.5-29.5 Nws | ≤0.2 | ≤0.3 | ≤0.5 | ≤ 0.02 | ≤ 0.02 | tshuav nyiaj li cas | 16.8-17.8 Nws | ≤0.2 |

| Qhov ceev (g / cm3) | Thermal conductivity (W / m · K) | Hluav taws xob tiv taus (μΩ·cm) |

| 8.3 | 17 | 45 |

| Alloy Qib

| Qhov nruab nrab linear expansion coefficient a, 10-6 / oC | |||||||

| 20-200 oC | 20-300 Nws oC ua | 20-400 Nws oC | 20-450 Nws oC | 20-500 oC | 20-600 Nws oC | 20-700 Nws oC | 20-800 Nws oC | |

| kovar | 5.9 | 5.3 | 5.1 | 5.3 | 6.2 | 7.8 ib | 9.2 ib | 10.2 |

Kovar nruab nrab linear expansion coefficient nyob rau hauv kab

| Alloy Qib | Specimen heat treatment system | Qhov nruab nrab linear expansion coefficient α,10-6 / oC | ||

| Cov | 20-300 oC | 20-400 oC | 20-450 oC | |

| Nyob rau hauv hydrogen huab cua rhuab mus rau 900 ± 20 oC, rwb thaiv tsev 1h, thiab ces rhuab mus rau 1100 ± 20 oC, rwb thaiv tsev 15min, kom tsis txhob ntau tshaj 5 oC / min tus nqi ntawm txias rau hauv qab 200 oC tso tawm | ------ | 4.6-5.2 | 5.1-5.5 | |

Kovar typical expansion coefficient

| Alloy Qib | Qhov nruab nrab linear expansion coefficient a, 10-6 / oC | |||||||

| Cov | 20-200 oC | 20-300 oC | 20-400 oC | 20-450 oC | 20-500 oC | 20-600 oC | 20-700 oC | 20-800 oC |

| 5.9 | 5.3 | 5.1 | 5.3 | 6.2 | 7.8 ib | 9.2 ib | 10.2 | |

Kovar Alloy muaj cov khoom hauv Sekonic hlau

Vim li cas Inconel Kovar?

1.Kovar muaj kev siv dav hauv kev lag luam hauv hluav taws xob, xws li cov khoom siv hlau txuas nrog lub hnab ntawv tawv iav.Cov khoom no yog siv rau cov khoom siv xws li lub hwj chim raj thiab X-ray raj, thiab lwm yam.

2.In lub semiconductor kev lag luam kovar yog siv nyob rau hauv hermetically kaw tej pob khoom rau ob qho tib si integrated thiab discrete circuit devices.

3.Kovar yog muab nyob rau hauv ntau hom ntawv los pab txhawb kev tsim khoom ntawm ntau yam hlau.Nws muaj cov yam ntxwv thermal expansion txuam nrog cov iav tawv.Siv rau kev sib txuam expansion pob qij txha ntawm cov hlau thiab iav los yog ceramics.

4.Kovar alloy yog lub tshuab nqus tsev melted, hlau-nickel-cobalt, tsis tshua muaj expansion alloy uas nws cov tshuaj muaj pes tsawg leeg yog tswj nyob rau hauv nqaim txwv kom paub meej meej uniform thermal expansion zog.Kev tswj kom zoo yog ua haujlwm nyob rau hauv kev tsim cov hlau no los xyuas kom meej lub cev thiab cov cuab yeej cuab tam kom yooj yim hauv kev sib sib zog nqus nqus, stamping thiab machining.

Kovar Alloy Daim ntawv thov teb:

● Kovar alloy tau siv los ua hermetic ntsaws ruaj ruaj nrog cov iav Pyrex nyuaj thiab cov ntaub ntawv ceramic.

●Qhov no alloy tau pom dav daim ntawv thov nyob rau hauv lub hwj chim raj, microwave tubes, transistors thiab diodes.Hauv kev sib txuas sib txuas, nws tau siv rau lub pob tiaj tiaj thiab pob khoom dual-hauv-kab.