Alloy Multimet N155 (AMS 5532 / AMS 5769)

Peb cov neeg ua haujlwm los ntawm kev cob qhia kev cob qhia.Kev paub txog kev txawj ntse, kev paub zoo ntawm kev pabcuam, kom ua tiav cov kev pabcuam xav tau ntawm cov neeg siv khoom rau AlloyMultimetal N155(AMS 5532 / AMS 5769), Raws li kev tsim khoom thiab xa tawm, peb txaus siab rau cov ntaub ntawv zoo heev hauv kev lag luam thoob ntiaj teb, tshwj xeeb hauv Asmeskas thiab Europe, vim tias peb cov khoom zoo tshaj plaws thiab cov nqi siv tau.

Peb cov neeg ua haujlwm los ntawm kev cob qhia kev cob qhia.Kev paub txog kev txawj ntse, kev paub zoo ntawm kev pabcuam, kom ua tiav cov kev pabcuam xav tau ntawm cov neeg siv khoomAlloy N155, Multimetal N155, UNS R30155, Thov koj xav tias dawb xa tuaj rau peb koj cov specifications thiab peb yuav teb rau koj asap.Peb tau txais ib pab kws tshaj lij engineering los pab rau txhua qhov kev xav tau tshwj xeeb.Cov qauv dawb tuaj yeem xa tuaj rau koj tus kheej kom paub qhov tseeb ntau dua.Yog li koj tuaj yeem ua tau raws li koj qhov kev xav tau, thov tiag tiag tsis them nqi tiv tauj peb.Koj tuaj yeem xa email rau peb thiab hu rau peb ncaj qha.Tsis tas li ntawd, peb zoo siab tos txais tuaj xyuas peb lub Hoobkas los ntawm thoob plaws lub ntiaj teb kom paub ntau ntxiv txog peb lub koom haum.nd cov khoom.Hauv peb txoj kev lag luam nrog cov tub lag luam ntawm ntau lub teb chaws, peb feem ntau ua raws li lub hauv paus ntsiab lus ntawm kev sib luag thiab kev sib raug zoo.Nws yog peb txoj kev cia siab rau kev ua lag luam, los ntawm kev sib koom tes, kev lag luam thiab kev phooj ywg rau peb txoj kev sib nrig sib pab.Peb tos ntsoov yuav tau txais koj cov lus nug.

Common Trade Names:Alloy N155, Multimet N155, R30155, W.Nr 1.4974

Alloy N155yog ib qho Nickel-Chromium-Cobalt alloy nrog ntxiv ntawm Molybdenum thiab Tungsten siv feem ntau hauv cov khoom uas xav tau lub zog siab txog 1350 ° F thiab oxidation tsis kam mus txog 1800 ° F.Nws cov khoom kub-kub muaj nyob rau hauv cov khoom raws li cov khoom siv (kev daws teeb meem ntawm 2150 ° F) thiab tsis nyob ntawm lub hnub nyoog-hardening.Multimet N155 yog siv nyob rau hauv ib tug xov tooj ntawm aerospace daim ntaub ntawv xws li tailpipes thiab tail cones, turbine blades, shafts thiab rotors, afterburner Cheebtsam thiab high-temperature bolts.

Alloy N155 Tshuaj muaj pes tsawg leeg

| Alloy | % | C | Si | Fe | Mn | P | S | Cr | Ni | Co | Mo | W | Nb | Cu | N |

| N155 | Min. | 0.08 ib | bal | 1.0 | 20.0 Nws | 19.0 Nws | 18.5 Nws | 2.5 | 2.0 | 0.75 ib | 0.1 | ||||

| Max. | 0.16 | 1.0 | 2.0 | 0.04 ib | 0.03 ib | 22.5 ib | 21.0 Nws | 21.0 Nws | 3.5 | 3.0 | 1.25 | 0.5 | 0.2 |

Alloy N155 Lub cev muaj zog

| Qhov ntom | 8.25 g / cm³ |

| Melting point | 2450 ℃ |

Alloy N155 Mechanical Properties

| xwm txheej | Tensile zog Rm N/mm² | Yield zog Rp 0. 2N/mm² | Elongation Raws li % | Brinell hardness HB |

| Kev kho mob | 690-965 : kuv | 345 | 20 | 82-92 : kuv |

Alloy N155 Txheem thiab Specifications

AMS 5532, AMS 5769, AMS 5794, AMS 5795

| Bar / Qws Forging | Hlau | Sawb / Coil | Ntawv / phaj |

| TIAB SA 5769 | TIAB SA 5794 | TIAB SA 5532 | TIAB SA 5532 |

Alloy N155 Muaj cov khoom lag luam hauv Sekonic hlau

Alloy N155 bar & Qws

Round tuav / tiaj tus tuav / Hex tuav, Loj Ntawm 8.0mm-320mm, Siv rau bolts, fastners thiab lwm yam khoom seem

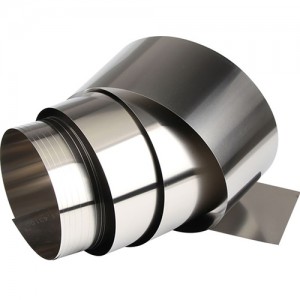

Alloy N155 vuam hlau & Caij nplooj ntoos hlav hlau

Muab nyob rau hauv vuam hlau thiab caij nplooj ntoos hlav hlau nyob rau hauv coil daim ntawv thiab txiav ntev.

Alloy N155 daim ntawv & phaj

Dav mus txog 1500mm thiab ntev mus txog 6000mm, Thickness ntawm 0.1mm mus rau 100mm.

Alloy N155 Forging Nplhaib

Forging Nplhaib los yog gasket, qhov loj me tuaj yeem ua raws li qhov ci ntsa iab thiab kev ua siab ntev ntev

Alloy N155 sawb & coil

Cov mob mos thiab tawv tawv nrog AB ci ntsa iab, dav txog 1000mm

Vim li cas Alloy N155?

Alloy N155 muaj kev tiv thaiv zoo rau corrosion nyob rau hauv tej yam xov xwm nyob rau hauv ob qho tib si oxidizing thiab txo tej yam kev mob.Thaum cov tshuaj kho cua sov kho, alloy N155 alloy muaj txog tib yam tsis kam rau nitric acid ib yam li stainless hlau.Nws muaj kev tiv thaiv zoo dua li cov hlau tsis muaj zog rau cov tshuaj tsis muaj zog ntawm hydrochloric acid.Nws tiv taus tag nrho cov concentrations ntawm sulfuric acid nyob rau hauv chav tsev kub.Cov hlau tuaj yeem raug machined, forged thiab txias-tsim los ntawm cov txheej txheem pa.

Lub alloy tuaj yeem welded los ntawm ntau yam arc thiab tsis kam-welding txheej txheem.Cov hlau no muaj xws li daim ntawv, sawb, phaj, hlau, coated electrodes, billet Tshuag thiab sane thiab peev castings.

Nws kuj tseem muaj nyob rau hauv daim ntawv ntawm cov khoom rov ua dua mus rau cov ntawv pov thawj chemistry.Feem ntau cov ntaub ntawv wrought ntawm n155 alloy raug xa mus rau hauv cov tshuaj kho cua sov kom paub tseeb tias cov khoom zoo.Daim ntawv yog muab cov kev daws teeb meem kub-kho ntawm 2150 ° F, rau ib lub sij hawm nyob ntawm cov thickness, ua raws li cov cua txias los yog dej quench.Bar Tshuag thiab phaj (1/4 nyob rau hauv. thiab hnyav dua) feem ntau yog cov tshuaj kho cua sov ntawm 2150 ° F ua raws li dej quench.

Alloy N155 raug kev txom nyem los ntawm nruab nrab oxidation tsis kam, ib tug nyiam rau tshav kub cuam tshuam cheeb tsam tawg thaum lub sij hawm vuam, thiab ib tug kuj dav scatter band ntawm txhua yam khoom.

Sekonic Metals Technology Co., Ltd ISO 9001 tsim nyog Hoobkas tshwj xeeb hauv kev tsim cov kub kub Alloys thiab Anti-Corrosion Alloys xws li Titanium Alloys, Precsion Alloys (Invar 36, Kovar 4J29, Mos Sib Nqus Alloys,) Hastelloy Alloys, Haynes Alloys, , Inconel Alloys, Incoloy Alloys Coblat Alloys (Haynes 25, Alloy 188, Stellite Alloys) ect Txij xyoo 1996.Tom qab ua tiav kev ua tiav zoo hauv kev lag luam hauv Suav teb, peb tau txuas ntxiv peb txoj kev lag luam mus rau thoob ntiaj teb txij li xyoo 2000Tag nrho cov khoom tau ua raws li cov qauv tsim nyog thiab tshuaj xyuas nruj me ntsis ua ntej xa peb cov factories.Raws li RoHS thiab IS09001: 2008 tus qauv, peb cov khoom tau muab rau hauv bar, pas nrig, hlau, phaj, sawb, ntawv, yeeb nkab ano tube, thiab lwm yam duab uas siv rau hauv ntau lub teb, xws li aviation & aerospace, metallurgy, machinery. , electronics chemicals, zog, siab zog, thiab lwm yam. Peb lub tuam txhab yuav ib txwm cia siab rau tus ntsuj plig: "zoo ua ntej, cov neeg muas zaub foremost" thiab pab rau cov domestic thiab txawv teb chaws cov neeg siv.