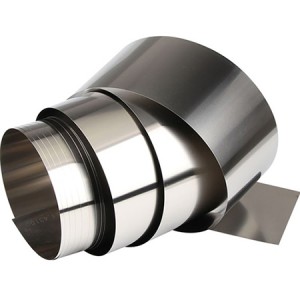

ERNiCrMo-3 Vuam Hlau Inconel 625 Vuam Hlau

ErNiCrMo-3 (Inconel 625 UNSNO6625)Vuam Hlau

♦ Welding Hlau npe: ErNiCrMo-3, Inconel 625 TIG/MIG Wire

♦ MOQ:15kg ua

♦ Daim ntawv: MIG (15kgs/spool), TIG (5kgs/box)

♦ Qhov Loj:Txoj kab uas hla 0.01mm-8.0mm

♦ Qhov Loj:Loj: 0.8mm / 1.0mm / 1.2mm / 1.6mm / 2.4mm / 3.2mm / 3.8mm / 4.0mm / 5.0mm

♦ Cov Qauv:Conforms to Certification AWS A5.14 ASME SFA A5.14

ErNiCrMo-3siv rau vuam 625 (N06625) alloy, 20 alloy, 825,25-6Mo, 9% Ni hlau los yog lwm yam molybdenum steel, kuj siv rau vuam ntawm txawv cov ntaub ntawv thiab corrosion resistant surfacing ntawm cov khoom nto.

Cov khoom siv zoo heev ntawm qhov kub thiab txias.Kev tiv thaiv corrosion muaj zog, kev ntxhov siab corrosion tawg, pitting thiab backlash corrosion nyob rau hauv ntau yam ntawm oxidation thiab txo cov xov xwm.

| C | Al | Si | Mn | Cr | Ni | Ti | Fe | S | Cu | Mo | P | Nb + Ta | Lwm tus |

| ≤ 0.10 | ≤ 0.40 | ≤0.50 | ≤0.50 | 20.0-23.0 Nws | ≥58.0 | ≤ 0.40 | ≤5.0 | ≤ 0.015 | ≤0.50 | 8.0-10.0 Nws | ≤ 0.02 | 3.15–4.15 dr hab | ≤0.50 |

| Txoj kab uas hla | Txheej txheem | Volt | Amps | Tiv thaiv Gas | |

| In | mm | ||||

| 0.035 ib | 0.9 | GMAW | 26-29 | 150-190 : kuv | Txau Hloov100% Argon |

| 0.045 ib | 1.2 | 28-32 : kuv | 180-220 : kuv | ||

| 1/16 | 1.6 | 29-33 : kuv | 200-250 | ||

| 1/16 | 1.6 | GTAW | 14-18 | 90-130 : kuv | 100% Argon |

| 3/32 | 2.4 | 15-20 | 120-175 : kuv | ||

| 1/8 | 3.2 | 15-20 | 150-220 : kuv | ||

| Qhov xwm txheej | Tensile zog MPa (ksi) | Yield zog MPa (ksi) | Elongation% |

| AWS Reauirement | 760 (110) hnub | Tsis tau teev tseg | Tsis tau teev tseg |

| Cov txiaj ntsig zoo li welded | 790 (115) hnub | 590 (85) hnub | 35 |

Vim li cas ERNiCrMo-3?

Cov ntsiab lus hlau tsawg, tuaj yeem siv rau hauv kev vuam ntawm nickel-chromium molybdenum alloy,

Nws tuaj yeem siv rau cladding thiab vuam ntawm cov hlau sib txawv xws li Ni-Cr-Mo alloy nrog stainless hlau thiab carbon hlau.

Nws muaj qhov zoo oxidation tsis kam thiab txo ib puag ncig.

Cov ntsiab lus siab ntawm molybdenum muab kev ntxhov siab zoo thiab ua haujlwm rau pitting thiab crevicecorrosion.

ERNiCrMo-3 Daim ntawv thov teb:

Nws yog tsim rau welding ntawm npib tsib xee-chrome-molybdenum alloy, xws li Inconel625, Incoy 825, thiab kuj siv tau rau vuam thiab surfacing ntawm nickel-base alloy thiab stainless hlau cov ntaub ntawv sib txawv.Nws tuaj yeem siv rau hauv ib puag ncig los ntawm qhov kub thiab txias mus rau 540 ℃.