Haynes25 siab kub resistant alloy

Haynes25 siab kub resistant alloy,

Haynes 25 muaj pes tsawg leeg, l605 ua, kev ua tau zoo, r30605 ua,

Cov npe lag luam: Haynes 25, Alloyl605 ua, Cobalt L605, GH5605, Udimet L605, UNSr30605 ua

Haynes 25 (AlloyL605) yog ib qho kev daws teeb meem ntxiv dag zog rau cobalt-chromium-tungsten npib tsib xee alloy nrog zoo kub-kub lub zog thiab zoo heev oxidation tsis kam mus rau 2000 ° F (1093 ° C).Cov hlau tseem muaj kev tiv thaiv zoo rau sulfidation thiab tsis kam hnav thiab galling.Alloy L-605 muaj txiaj ntsig zoo hauv kev siv roj turbine xws li rings, blades thiab combustion chamber parts (daim ntawv fabrications) thiab tuaj yeem siv tau rau hauv kev lag luam rau cov ntawv thov xws li muffles lossis liners hauv qhov kub kub.

Haynes 25 (Alloy L605) Chemical Composition

| C | Cr | Ni | Fe | W | Co | Mn | Si | S | P |

| 0.05-0.15 dr hab | 19.0-21.0 Nws | 9.0-11.0 Nws | ≦ 3.0 | 14.0-16.0 Nws | tshuav nyiaj li cas | 1.0-2.0 Nws | ≦ 0.4 | ≦ 0.03 | ≦ 0.04 |

Haynes 25 (Alloy L605) Lub cev muaj zog

| Qhov ntom (g / cm3) | Melting point (℃) | Tshwj xeeb kub muaj peev xwm (J / kg ℃) | Hluav taws xob resistivity (Ω·cm) | Thermal conductivity (W / m ℃) |

| 9.27 ib | 1300-1410 Nws | 385 | 88.6 × 10 E-6 | 9.4 ib |

Haynes 25 (Alloy L605) Mechanical Properties

Sawv cev Tensile Properties, Sheet

| Kub, ° F | 70 | 1200 | 1400 | 1600 | 1800 |

| Qhov kawg Tensile Strength, ksi | 146 | 108 | 93 | 60 | 34 |

| 0.2% Yield zog, ksi | 69 | 48 | 41 | 36 | 18 |

| Elongation,% | 51 | 60 | 42 | 45 | 32 |

Yam Kev Nyuaj Siab-Rupture Strength

| Kub, ° F | 1200 | 1400 | 1500 | 1600 | 1700 | 1800 |

| 100 h, ksi | 69 | 36 | 25 | 18 | 12 | 7 |

| 1,000 teev, ksi | 57 | 26 | 18 | 12 | 7 | 4 |

Haynes 25 (Alloy L605) Cov Qauv thiab Cov Qauv

AMS 5537, AMS 5796, EN 2.4964, GE B50A460, UNSr30605 ua, Werkstoff 2.4964

| Bar / Qws | Hlau / Vuam | Sawb / Coil | Ntawv / phaj | Tube / Tube |

| TIAB SA 5537 | AMS 5796/5797 | TIAB SA 5537 | TIAB SA 5537 | - |

Haynes 25 (Alloy L605) Cov khoom muaj nyob rau hauv Sekonic hlau

Alloy L605 Bars & Qws

Round tuav / Pav ca / Hex tuav, Loj Ntawm 8.0mm-320mm, Siv rau bolts, fastners thiab lwm yam khoom seem

Alloy L605 vuam hlau

Muab nyob rau hauv vuam hlau thiab caij nplooj ntoos hlav hlau nyob rau hauv coil daim ntawv thiab txiav ntev.

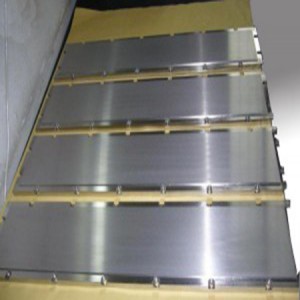

Alloy L605 daim ntawv & phaj

Dav mus txog 1500mm thiab ntev mus txog 6000mm, Thickness ntawm 0.1mm mus rau 100mm.

Alloy L605 Gasket / Nplhaib

Dimension tuaj yeem kho nrog qhov ci ntsa iab thiab kev ua siab ntev ntev.

Alloy L605 sawb & coil

Cov mob mos thiab tawv tawv nrog AB ci ntsa iab, dav txog 1000mm

Vim li cas Inconel Haynes 25 (Alloy L605)?

•Zoo kub kub lub zog

•Oxidation resistant rau 1800 ° F

•Galling resistant

•Resistant rau marine ib puag ncig, acids thiab lub cev kua

Haynes 25 (Alloy L605) Daim ntawv thov teb:

•Gas turbine cav Cheebtsam xws li combustion chambers thiab afterburners

•Kub kub pob bearings thiab cov kabmob sib tw

•Springs

•Lub plawv li qub

Haynes 25 alloy yog cobalt-nickel-cr-w alloy nrog - kub lub zog thiab -1800 ° F (980 ° C) oxidation ib puag ncig, ntev raug, thiab - vulcanization kuj. tau siv rau casting qhov chaw.Lwm cov yam ntxwv ntxim nyiam muaj xws li tsis kam hnav thiab tsim kua muag ntawm cov hlau.Available khoom daim ntawv: cov ntaub ntawv yog tsim nyob rau hauv daim ntawv ntawm daim hlau, nplooj ntawv, strips, billets, rods, xov hlau, coated electrodes, raj thiab tubes.Product specifications : Haynes 25 Alloy yog lub npe R30605.Bars, bars, Hlau thiab Forgings: AMS 5759 (bars, rings thiab forgings), Sheets, nplooj ntawv thiab strips: AMS 5537 (Cov ntawv, strips thiab ntawv) Lwm yam: AMS 5796 (Wire) thiab AMS 5797 (Coated Vuam electrodes)