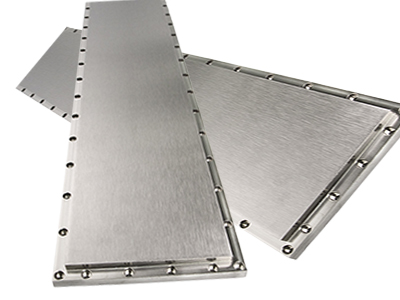

Titanium Phaj Target

Titanium Target: Peb siv titanium alloy billet, los yog phaj rau machined rau hauv titanium lub hom phiaj.Cov ntsiab lus impurity ntawm industrial ntshiab titanium yog ntau tshaj li cov tshuaj ntshiab titanium, yog li nws lub zog thiab hardness yog me ntsis siab dua.Nws cov khoom siv kho tshuab thiab tshuaj lom neeg zoo ib yam li cov hlau tsis muaj steel.Piv nrog titanium alloy, ntshiab titanium muaj zog zoo dua thiab muaj oxidation zoo dua.Nws zoo dua li austenitic stainless hlau, tab sis nws cov cua sov tsis zoo.TA1, TA2, TA3 nce nyob rau hauv impurity cov ntsiab lus, mechanical zog thiab hardness nce nyob rau hauv kev txiav txim, tab sis yas toughness txo nyob rau hauv kev txiav txim.

• Tittanium Phaj TargetQib 1, Qib 2, Qib 5, Qib 5, Qib 7, Qib 9, Qib 11, Qib 12, Qib 16, Qib 23 thiab lwm yam

• Hom:Round Target, Pipe Target, Phaj Target.ect

• DimensionLoj: 60/80/120 (W) × 6/8/12 (T) × 519/525/620 (L) & 60-800 (W) × 6-40 (T) × 600-2000 (L)Customized

•Surface:ci ntsa iab los yog Acid pickling nto

• Cov ntawv thov: siv nyob rau hauv cov khoom siv sib cais semiconductor, cov vaj huam sib luag tiaj tus, cov khoom siv hluav taws xob cia, cov txheej txheem sputtering, workpiece nto txheej, iav txheej kev lag luam, thiab lwm yam.

| Titanium Alloys Khoom Lub Npe | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr 2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| gr 7 | UNS R52400 | Ti-0.20 Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15 Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05 Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

♦ Titanium Alloys Chemical Composition ♦

| Qib | Tshuaj muaj pes tsawg leeg, qhov hnyav feem pua (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Lwm Yam Khoom Max.txhua | Lwm Yam Khoom Max.tag nrho | |

| Gr1 | 0.08 ib | 0.18 | 0.03 ib | 0.015 ib | 0.20 ib | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr 2 | 0.08 ib | 0.25 | 0.03 ib | 0.015 ib | 0.30 Nws | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 ib | 0.25 | 0.03 ib | 0.015 ib | 0.30 Nws | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr 5 | 0.08 ib | 0.20 ib | 0.05 Nws | 0.015 ib | 0.40 Nws | 5.56.75 ib | 3.5 4.5 | — | — | — | — | 0.1 | 0.4 |

| gr 7 | 0.08 ib | 0.25 | 0.03 ib | 0.015 ib | 0.30 Nws | — | — | 0.12 0.25 Nws | — | 0.12 0.25 Nws | — | 0.1 | 0.4 |

| gr9 ua | 0.08 ib | 0.15 | 0.03 ib | 0.015 ib | 0.25 | 2.5 3.5 | 2.0 3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr 11 | 0.08 ib | 0.18 | 0.03 ib | 0.15 | 0.2 | — | — | 0.12 0.25 Nws | — | — | — | 0.1 | 0.4 |

| Gr 12 | 0.08 ib | 0.25 | 0.03 ib | 0.15 | 0.3 | — | — | — | — | 0.6 0.9 ib | 0.2 0.4 ib | 0.1 | 0.4 |

| Gr 16 | 0.08 ib | 0.25 | 0.03 ib | 0.15 | 0.3 | — | — | 0.04 0.08 Nws | — | — | — | 0.1 | 0.4 |

| Gr 23 | 0.08 ib | 0.13 | 0.03 ib | 0.125 Nws | 0.25 | 5.5 6.5 | 3.5 4.5 | — | — | — | — | 0.1 | 0.1 |

♦Titanum alloyLub cev muaj zog ♦

| Qib | Lub cev muaj zog | |||||

| Tensile zog Min | Yield zog Tsawg (0.2%, offset) | Elongation hauv 4D Min (%) | Kev txo qis ntawm cheeb tsam Min (%) | |||

| ksi ua | MPa | ksi ua | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr 2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 ib | 15 | 25 |

| Gr 5 | 130 | 895 ib | 120 | 828 ib | 10 | 25 |

| gr 7 | 50 | 345 | 40 | 275 | 20 | 30 |

| gr9 ua | 90 | 620 | 70 | 483 ib | 15 | 25 |

| Gr 11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr 12 | 70 | 483 ib | 50 | 345 | 18 | 25 |

| Gr 16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr 23 | 120 | 828 ib | 110 | 759 ib | 10 | 15 |