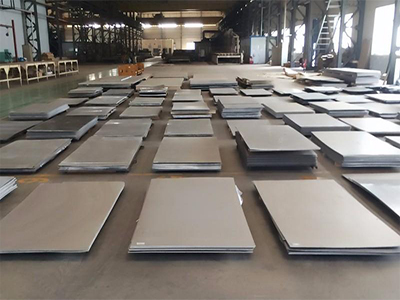

Titanium Sheet thiab Phaj

• Cov ntaub ntawv titaniumQauv: Gr1, Gr2, Gr4, Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23

• Cov duab: Forging Sheet, Cold Rolling Sheet, Kub Rolling Sheet

• Dimension:Thickness: 0.3 ~ 5mm, Dav: 400 ~ 3000mm, Ntev: ≤6000mm

• Cov xwm txheej:Kub Forging & Kub Rolling, Txias Rolled, SolutionAnnealed

• Cov qauv:ASTM B265, AMS 4911, AMS 4902, ASTM F67, ASTM F136 thiab lwm yam

| Titanium Alloys Khoom Lub Npe | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr 2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| gr 7 | UNS R52400 | Ti-0.20 Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15 Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05 Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

Titanium Sheet thiab Titanium Phaj:Peb tsuas yog muab cov ntawv ntshiab titanium ntawm Gr1, Gr2, Gr4 qib;Rau titanium alloy daim ntawv, Peb tsuas yog muab Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 thiab lwm yam qib, Lawv yog tsim los ntawm titanium phaj nrog ntxiv txias dov;cov txheej txheem ntau lawm ntawm titanium ntawv yog qhov nyuaj dua.Kev tswj deformation yog nruj dua nyob rau hauv cov txheej txheem ntawm dov.Qhov ntawd tuaj yeem txiav ntau qhov sib txawv raws li tus neeg siv khoom xav tau, ua kom luv luv lub sijhawm xa khoom.

♦ Titanium Sheet Tshuaj muaj pes tsawg leeg ♦

| Qib | Tshuaj muaj pes tsawg leeg, qhov hnyav feem pua (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Lwm Yam Khoom Max.txhua | Lwm Yam Khoom Max.tag nrho | |

| Gr1 | 0.08 ib | 0.18 | 0.03 ib | 0.015 ib | 0.20 ib | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr 2 | 0.08 ib | 0.25 | 0.03 ib | 0.015 ib | 0.30 Nws | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 ib | 0.25 | 0.03 ib | 0.015 ib | 0.30 Nws | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr 5 | 0.08 ib | 0.20 ib | 0.05 Nws | 0.015 ib | 0.40 Nws | 5.56.75 ib | 3.5 4.5 | — | — | — | — | 0.1 | 0.4 |

| gr 7 | 0.08 ib | 0.25 | 0.03 ib | 0.015 ib | 0.30 Nws | — | — | 0.12 0.25 Nws | — | 0.12 0.25 Nws | — | 0.1 | 0.4 |

| gr9 ua | 0.08 ib | 0.15 | 0.03 ib | 0.015 ib | 0.25 | 2.5 3.5 | 2.0 3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr 11 | 0.08 ib | 0.18 | 0.03 ib | 0.15 | 0.2 | — | — | 0.12 0.25 Nws | — | — | — | 0.1 | 0.4 |

| Gr 12 | 0.08 ib | 0.25 | 0.03 ib | 0.15 | 0.3 | — | — | — | — | 0.6 0.9 ib | 0.2 0.4 ib | 0.1 | 0.4 |

| Gr 16 | 0.08 ib | 0.25 | 0.03 ib | 0.15 | 0.3 | — | — | 0.04 0.08 Nws | — | — | — | 0.1 | 0.4 |

| Gr 23 | 0.08 ib | 0.13 | 0.03 ib | 0.125 Nws | 0.25 | 5.5 6.5 | 3.5 4.5 | — | — | — | — | 0.1 | 0.1 |

♦Titanum alloy daim ntawvLub cev muaj zog ♦

| Qib | Lub cev muaj zog | |||||||

| Tensile zog Min | Yield zogTsawg (0.2%, offset) | Elongation hauv 4D Min (%) | Kev txo qis ntawm cheeb tsam Min (%) | Khoov Test (Radius ntawm Mandrel) | ||||

| ksi ua | MPa | ksi ua | MPa | 1.8 hli Hauv tuab | 1.8-4.8 hli thickness | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5 t ib | 2.0t ib |

| Gr 2 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0t ib | 2.5 t ib |

| Gr4 | 80 | 550 | 70 | 483 ib | 15 | 25 | 2.5 t ib | 3.0t ua |

| Gr 5 | 130 | 895 ib | 120 | 828 ib | 10 | 25 | 4.5t :ua | 5.0t ib |

| gr 7 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0t ib | 2.5 t ib |

| gr9 ua | 90 | 620 | 70 | 483 ib | 15 | 25 | 2.5 t ib | 3.0t ua |

| Gr 11 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5 t ib | 2.0t ib |

| Gr 12 | 70 | 483 ib | 50 | 345 | 18 | 25 | 2.0t ib | 2.5 t ib |

| Gr 16 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0t ib | 2.5 t ib |

| Gr 23 | 120 | 828 ib | 110 | 759 ib | 10 | 15 | 4.5t :ua | 5.0t ib |