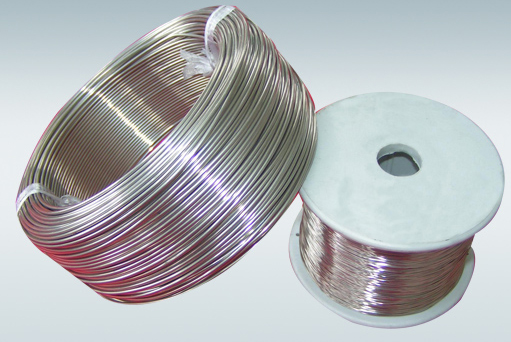

Titanium hlau

Titanium hlauCov titanium hlau feem ntau yog siv rau vuam, thav duab, phais kev cog hniav, kho kom zoo nkauj, electroplating hanging fixture.Sed nyob rau hauv zus tau tej cov spherical titanium hmoov.

Hlau siv lub titanium bar lossis titanium slab tinto pwm los ua cov txheej txheem, vim yog cov nyhuv rub, lub titanium bar deforms nyob rau hauv kub kub thaum los ntawm lub qhov ntawm lub pwm.Txoj kev hla yog txo, thiab qhov ntev nce.Stretching nyob rau hauv ib tug rhuab lub xeev pab tshem tawm cov kev ntxhov siab nyob rau hauv thiab txhim kho cov plasticity ntawm titanium hlau.Nws zoo txhim kho qhov tseeb ntawm titanium hlau, thiab qhov chaw tiav, uas tuaj yeem ua tiav qhov kev ua tau zoo dua.

• Cov khoom siv titanium hlauQib 1, Qib 2, Qib 5, Qib 5, Qib 7, Qib 9, Qib 11, Qib 12, Qib 16, Qib 23 thiab lwm yam

• Cov ntaub ntawv hlau: Spool hauv Coil, Txiav ntev / Ncaj

• Txoj kab uas hlaLoj: 0.05mm-8.0mm

• Cov xwm txheej:Kev daws Annealed, Kub dov, Stretching

• Nto:Pickling Dawb, Ci Polished, Acid Ntxuav, Dub oxide

• Cov qauv:ASTM B863, AWS A5.16, ASTM F67, ASTM F136 thiab lwm yam

| Titanium Alloys Khoom Lub Npe | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr 2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| gr 7 | UNS R52400 | Ti-0.20 Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15 Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05 Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

♦ Titanium Hlau Chemical Composition ♦

| Qib | Tshuaj muaj pes tsawg leeg, qhov hnyav feem pua (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Lwm Yam Khoom Max.txhua | Lwm Yam Khoom Max.tag nrho | |

| Gr1 | 0.08 ib | 0.18 | 0.03 ib | 0.015 ib | 0.20 ib | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr 2 | 0.08 ib | 0.25 | 0.03 ib | 0.015 ib | 0.30 Nws | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 ib | 0.25 | 0.03 ib | 0.015 ib | 0.30 Nws | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr 5 | 0.08 ib | 0.20 ib | 0.05 Nws | 0.015 ib | 0.40 Nws | 5.5-6.75 ib | 3.5 4.5 | — | — | — | — | 0.1 | 0.4 |

| gr 7 | 0.08 ib | 0.25 | 0.03 ib | 0.015 ib | 0.30 Nws | — | — | 0.12 0.25 Nws | — | 0.12 0.25 Nws | — | 0.1 | 0.4 |

| gr9 ua | 0.08 ib | 0.15 | 0.03 ib | 0.015 ib | 0.25 | 2.5 3.5 | 2.0 3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr 11 | 0.08 ib | 0.18 | 0.03 ib | 0.15 | 0.2 | — | — | 0.12 0.25 Nws | — | — | — | 0.1 | 0.4 |

| Gr 12 | 0.08 ib | 0.25 | 0.03 ib | 0.15 | 0.3 | — | — | — | — | 0.6 0.9 ib | 0.2 0.4 ib | 0.1 | 0.4 |

| Gr 16 | 0.08 ib | 0.25 | 0.03 ib | 0.15 | 0.3 | — | — | 0.04 0.08 Nws | — | — | — | 0.1 | 0.4 |

| Gr 23 | 0.08 ib | 0.13 | 0.03 ib | 0.125 Nws | 0.25 | 5.5 6.5 | 3.5 4.5 | — | — | — | — | 0.1 | 0.1 |

♦Titanum alloy hlauLub cev muaj zog ♦

| Qib | Lub cev muaj zog | |||||

| Tensile zog Min | Yield zog Tsawg (0.2%, offset) | Elongation hauv 4D Min (%) | Kev txo qis ntawm cheeb tsam Min (%) | |||

| ksi ua | MPa | ksi ua | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr 2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 ib | 15 | 25 |

| Gr 5 | 130 | 895 ib | 120 | 828 ib | 10 | 25 |

| gr 7 | 50 | 345 | 40 | 275 | 20 | 30 |

| gr9 ua | 90 | 620 | 70 | 483 ib | 15 | 25 |

| Gr 11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr 12 | 70 | 483 ib | 50 | 345 | 18 | 25 |

| Gr 16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr 23 | 120 | 828 ib | 110 | 759 ib | 10 | 15 |

♦♦♦ Titanium Alloy Khoom Nta: ♦♦♦

•Qib 1: Ntshiab Titanium, kuj muaj zog thiab siab ductility.

•Qib 2: Cov ntshiab titanium feem ntau siv.Qhov zoo tshaj plaws ua ke ntawm lub zog

•Qib 3: Siab zog Titanium, siv rau Matrix-phaj nyob rau hauv lub plhaub thiab lub raj kub exchangers

•Qib 5: Feem ntau tsim titanium alloy.Siab zog heev.siab kub tsis kam.

•Qib 9: muaj zog heev thiab corrosion kuj.

•Qib 12: Cov cua sov zoo dua li cov ntshiab Titanium.Cov ntawv thov rau Qib 7 thiab Qib 11.

•Qib 23: Titanium-6Aluminum-4Vanadium rau daim ntawv thov kev phais.