UmCO50 swb thaiv rau kauj ruam rauv

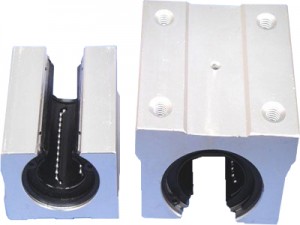

Cua sov rauv UMCO50 slider, CO50 tshav kub tiv thaiv ncoo, CO50 slider ua raws li daim duab

UMCO50 alloy ua los ntawm lub tshuab nqus tsev induction smelting, lub tshuab nqus tsev yog casting, siv rau dov phaj cua sov rauv txhawb thaiv, nws muaj qhov kub thiab txias kev ua tau zoo (1000-1300 ℃), zoo kub oxidation kuj thiab hnav tsis kam.

Co20, Co40 thiab Co50 pads tuaj yeem txo qhov tshwm sim ntawm laminar denudation nyob rau sab saum toj ntawm lub ncoo, txo qhov siab poob ntawm lub ncoo thiab txuas ntxiv lub neej kev pab cuam ntawm lub ncoo, txhawm rau txhim kho cov cua sov kom zoo ntawm daim ntawv thiab txo qhov "dub cim" kub qhov sib txawv ntawm lub billet.Qhov kev ua tau zoo ntawm cov ntaub qhwv los ntawm qhov tsim nyog sab hauv crystalline qauv.Heating rauv CO50 slider CO50 kub resisting ncoo CO50 slider

Umco50 Chemical Compositions

| C | Cr | Si | Mn | P | S | Fe | Co |

| 0.05-0.12 dr hab | 27.0-29.0 Nws | 0.5-1.0 hli | 0.5-1.0 hli | ≤ 0.02 | ≤ 0.02 | Bal | 48.0-52.0 Nws |

UMCo50 Cov khoom muaj nyob rau hauv Sekonic Hlau

Vim li cas UMCo50?

•Anti-corrosion nyob rau hauv dilute sulfuric acid thiab boiling nitric acid, ceev corrosion nyob rau hauv hydrochloric acid.

•Nws muaj zog oxidation tsis kam tshaj 25Cr-20Ni nyob rau hauv cov huab cua mus rau 1200 ° C.

•Thaum cov roj sulfur-muaj roj siv los ua roj, nws muaj kev tiv thaiv corrosion siab nyob rau hauv ib puag ncig sulfur oxide.

•Anti-corrosion ntawm molten tooj liab, tab sis ceev corrosion ntawm molten aluminium.

UMCo50 Daim ntawv thov teb:

• Cov khoom siv Petrochemical residual roj vaporization rauv forging nozzles

• Kub kub thiab siab siab li qub

• Internal combustion engine tso li qub

• Sealing nto

• Cov pwm kub kub

• Chav turbine hniav

• Sealing nto, qhov cub qhov chaw Tos, saw saw qhia daim hlau, plasma spray vuam