Tom ntej: Incoloy 825 Flange

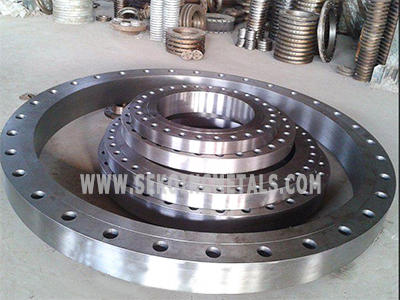

Incoloy 825 (W.Nr 2.4858) Flange

Flange Khoom :Tom ntej: Incoloy Alloy 825 (UNS N08825)

Hom Flange:Raws li cov neeg thov kev thov

Hnub tim:15-30 hnub

Them Nyiaj:T / T, L / C, Paypal, thiab lwm yam

Sekoinc Metals Main tsim thiab muab tshwj xeeb alloys Flanges, peb txais cov qauv txiav txim

alloy 825yog lub siab nickel cov ntsiab lus muab cov alloy zoo kev nyuaj siab corrosion cracking kuj.Corrosion kuj yog qhov zoo hauv ntau yam xov xwm, xws li sulfuric, phosphoric, nitric thiab organic acids, alkali hlau xws li sodium hydroxide, potassium hydroxide thiab hydrochloric acid daws.

Kev ua tau zoo tag nrho ntawm Incoloy 825 yog pom nyob rau hauv lub tshuab hluav taws xob sib txuas nrog ntau yam kev tawm tsam, xws li sulfuric acid, nitric acid thiab sodium hydroxide, txhua yam ua tiav hauv tib lub cuab yeej.

| Alloy | % | Ni | Cr | Mo | Fe | C | Mn | Si | S | Cu | Al | Ti | P |

| 825 ib | Min. | 38.0 Nws | 19.5 Nws | 2.5 | 22.0 Nws | - | - | - | - | 1.5 | 0.6 | - | |

| Max. | 46.0 ib | 23.5 Nws | 3.5 | - | 0.05 Nws | 1.0 | 0.5 | 0.03 ib | 3.0 | 0.2 | 1.2 | 0.03 ib |

| Qhov ntom | 8.14 g / cm³ |

| Melting point | 1370-1400 ℃ |

| xwm txheej | Tensile zog Rm N/mm² | Yield zog Rp 0. 2N/mm² | Elongation Raws li % | Brinell hardness HB |

| Kev kho mob | 550 | 220 | 30 | ≤200 |

• Hom Flange:

→ Vuam phaj flange (PL) → Slip-on Neck Flange (SO)

→ Weld caj dab flange (WN) → Integral flange (IF)

→ Socket vuam flange (SW) → Threaded flange (Th)

→ Lapped joint flange (LJF) → Dig muag flange (BL(s))

♦ Main Flange Materials Peb tsim

• Stainless hlau:ASTM A 182 Cov Lus Qhia

Qib F304 / F304L, F316 / F316L, F310, F309, F317L, F321, F904L, F347

Duplex Stainless Hlau: Qib F44 / F45 / F51 / F53 / F55 / F61 / F60

• Nickel Alloys: ASTM B472, ASTM B564, ASTM B160

Monel 400,Nickel 200, Incoloy 825, Incoly 926, Inconel 601, Inconel 718

Hastelloy C276, Alloy 31, Alloy 20, Inconel 625, Inconel 600

• Titanium alloys:Gr1/Gr2/Gr3/Gr4/GR5/Gr7/Gr9/Gr11/Gr12

♦ Cov Qauv:

ANSI B16.5 Class150, 300, 600, 900, 1500 (WN, SO, BL, TH, LJ, SW)

DIN2573,2572,2631,2576,2632,2633,2543,2634,2545 (PL,SO,WN,BL,TH)

Incoloy 825 Cov khoom muaj nyob rau hauv Sekonic Hlau

Vim li cas Incoloy 825?

825 alloy yog ib hom kev lag luam dav dav hlau, uas muaj cov kua qaub thiab alkali corrosion kuj nyob rau hauv oxidation thiab txo ib puag ncig thiab ua haujlwm zoo rau kev ntxhov siab corrosion cracking rau nws siab nickel muaj pes tsawg leeg. acid, phosphoric acid, nitric acid thiab organic acid, rau alkali, xws li sodium hvdroxide, potassium hvdroxide thiab hvdrochloric acid tov.Qhov kev ua tau zoo dua ntawm 825 alloy qhia tau hais tias nyob rau hauv nuclear burning dissolver ntawm ntau yam corrosion nruab nrab, xws li sulfuric acid, nitric acid thiab sodium hvdroxide yog tag nrho cov nyob rau hauv tib cov khoom.

•Zoo tiv thaiv kev ntxhov siab corosion tawg.

•Zoo tiv taus pitting thiab crevice corrosion

•Zoo tiv thaiv oxidization thiab tsis oxidizing acid.

•Zoo txhua yam khoom ntawm chav tsev kub lossis txog li 550 ℃

•Daim ntawv pov thawj ntawm kev tsim cov hlab ntsha siab ntawm 450 ℃

Incoloy 825 Daim ntawv thov teb:

•Cheebtsam xws li cua sov coils, tso tsheb hlau luam, crates, baskets thiab chains nyob rau hauv sulfuric acid pickling nroj tsuag

•Hiav txwv-dej-txias cua kub exchangers, offshore khoom piping systems;cov raj thiab cov khoom siv hauv cov khoom siv qaub qaub

•Thaum tshav kub kub exchangers, evaporators, scrubbers, dip kav thiab lwm yam nyob rau hauv phosphoric acid ntau lawm

•Cua txias cua sov exchangers nyob rau hauv roj refineries

•Kev ua zaub mov

•Tshuaj cog