Kev xaiv cov khoom siv los ntawm ntau yam khoom siv yog ib txoj haujlwm txwv los ntawm ntau yam.Yog li ntawd, yuav ua li cas xaiv cov khoom ntawm cov khoom yog ib qho tseem ceeb ntawm cov khoom tsim.Lub hauv paus ntsiab lus ntawm kev xaiv cov khoom siv tshuab yog: cov ntaub ntawv yuav tsum tau ua raws cov kev cai ntawm kev siv cov khoom thiabmuaj zoo technology thiab kev lag luam.

Cov kev xav tau ntawm kev siv cov khoom siv tshuab yog raws li hauv qab no:

1) Kev ua haujlwm thiab kev thauj khoom ntawm cov khoom thiab cov kev xav tau kom tsis txhob muaj cov ntaub ntawv ua tsis tiav.

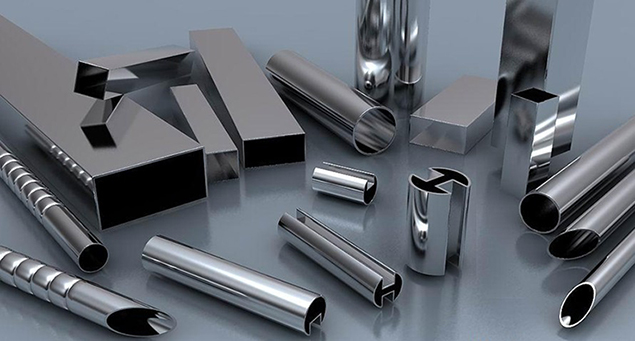

Kev ua haujlwm yog hais txog cov yam ntxwv ntawm ib puag ncig, kev ua haujlwm kub thiab qib ntawm kev sib txhuam thiab hnav ntawm qhov chaw.Qhov chaw ua haujlwm kub thiab av noo ib puag ncig lossis corrosive media, lawv cov ntaub ntawv yuav tsum muaj cov xeb zoo thiab corrosion kuj, nyob rau hauv rooj plaub no, tuaj yeem ua ntej xav txog kev siv. ntawm stainless hlau, tooj liab alloy.Qhov kev cuam tshuam ntawm kev ua haujlwm kub ntawm cov khoom xaiv feem ntau muaj ob yam: ntawm ib sab, nws yog ib qho tsim nyog yuav tsum xav txog cov kab nthuav dav coefficient ntawm cov ntaub ntawv ntawm ob qhov chaw uas koom tes nrog ib leeg yuav tsum tsis txhob sib txawv. ntau, yog li tsis tsim kom muaj kev ntxhov siab ntau dhau los yog xoob haum thaum qhov kub hloov pauv; Ntawm qhov tod tes, kev hloov pauv ntawm cov khoom siv hluav taws xob nrog qhov kub thiab txias yuav tsum tau txiav txim siab.Qhov chaw ua haujlwm hauv kev sib txhuam zawv zawg, txhawm rau txhim kho qhov tawv tawv, hauv Txhawm rau txhim kho kev hnav tsis kam, yuav tsum xaiv qhov tsim nyog rau kev kho deg ntawm cov hlau tawv tawv, carburized steel, nitride steel thiab lwm yam los yog xaiv kev sib txhuam txo thiab hnav tsis kam ntawm cov ntaub ntawv zoo.

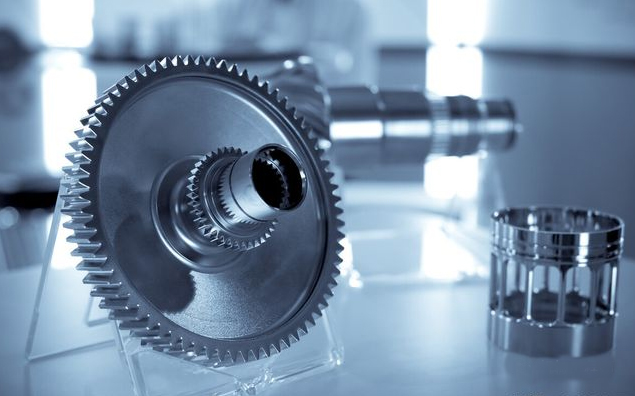

Load condition hais txog qhov loj thiab qhov xwm ntawm lub load thiab kev ntxhov siab nyob rau hauv ib feem.Brittle cov ntaub ntawv nyob rau hauv lub hauv paus ntsiab lus tsuas yog tsim nyog rau manufacturing qhov chaw uas ua hauj lwm nyob rau hauv static loads; nyob rau hauv cov ntaub ntawv ntawm kev cuam tshuam, cov ntaub ntawv yas yuav tsum tau siv los ua cov khoom tseem ceeb; Qhov saum npoo ntawm qhov loj dua qhov kev ntxhov siab, yuav tsum xaiv qhov kev kho deg ntawm cov ntaub ntawv, xws li cov hlau tawv tawv; Rau qhov chaw raug kev ntxhov siab, cov ntaub ntawv qaug zog yuav tsum raug xaiv; Rau qhov chaw nyob rau hauv kev cuam tshuam, cov ntaub ntawv uas muaj kev cuam tshuam loj yuav tsum tau xaiv. ; Rau qhov loj nyob ntawm lub zog thiab qhov loj thiab qhov zoo ntawm cov khoom raug txwv, yuav tsum xaiv cov ntaub ntawv muaj zog; Rau qhov chaw uas nws qhov ntev yog nyob ntawm qhov nruj, cov khoom siv nrog cov elastic moduli loj yuav tsum raug xaiv.

Feem ntau, cov khoom ntawm cov khoom siv hlau tuaj yeem txhim kho thiab txhim kho los ntawm kev kho cua sov.Yog li ntawd, nws yog ib qho tsim nyog yuav tsum ua kom tag nrho cov kev siv ntawm kev kho cua sov los tsim cov peev txheej ntawm cov ntaub ntawv.Rau qhov feem ntau siv modulated steel, cov dawb paug nrog cov khoom siv sib txawv tuaj yeem tau txais vim qhov sib txawv tempering.Qhov siab dua qhov tempering. qhov kub thiab txias, qhov qis dua qhov hardness thiab nruj ntawm cov khoom, thiab cov plasticity zoo dua. Yog li ntawd, thaum xaiv cov khoom siv ntau yam, cov txheej txheem kev kho cua sov yuav tsum tau teev nyob rau tib lub sijhawm, thiab qhia rau ntawm daim duab.

2) Kev txwv ntawm qhov loj thiab qhov zoo ntawm qhov chaw.

Qhov luaj li cas thiab qhov zoo ntawm qhov loj thiab cov khoom siv ntau yam thiab kev tsim khoom dawb paug.Production ntawm casting dawb paug feem ntau tsis tuaj yeem raug txwv los ntawm qhov loj thiab loj loj; Hauv kev tsim cov forging dawb paug, nws yog ib qho tsim nyog yuav tsum tau them sai sai rau lub peev xwm ntawm forging. machinery thiab khoom siv.Ntxiv, qhov loj ntawm qhov chaw thiab qhov zoo ntawm qhov loj thiab cov khoom hnyav piv, yuav tsum kom deb li deb tau los xaiv qhov hnyav piv ntawm cov ntaub ntawv loj, thiaj li yuav txo tau qhov loj thiab qhov zoo ntawm qhov chaw.

3) Qhov tseem ceeb ntawm cov khoom hauv tag nrho lub tshuab thiab cov khoom siv.

4) Lwm cov kev cai tshwj xeeb (xws li rwb thaiv tsev, diamagnetic, thiab lwm yam).

Kev Siv Tshuab

Kev Siv Tshuab

Txhawm rau ua kom cov khoom siv tau yooj yim, qhov nyuaj ntawm cov qauv tsim, qhov loj me thiab hom dawb paug yuav tsum raug txiav txim siab thaum xaiv cov khoom siv.Rau qhov chaw nrog cov duab thiab loj loj, yog tias casting dawb paug raug txiav txim siab, kev ua haujlwm zoo yuav tsum raug xaiv; Vuam dawb yog suav tias yog, qis carbon steel nrog zoo vuam kev ua tau zoo yuav tsum raug xaiv.Rau cov duab yooj yim, me me, loj batch ntawm qhov chaw, haum rau stamping thiab tuag forging, yuav tsum xaiv cov khoom yas zoo.Rau qhov chaw uas xav tau kev kho cua sov, cov khoom siv yuav tsum muaj kev kho cua sov zoo.Ntxiv, qhov ua haujlwm ntawm cov khoom siv nws tus kheej thiab kev ua haujlwm tom qab kev kho cua sov yuav tsum tau txiav txim siab.

Kev xav tau nyiaj txiag

Kev xav tau nyiaj txiag

1) Tus nqi txheeb ze ntawm cov khoom nws tus kheej

Raws li qhov ua tau raws li qhov yuav tsum tau ua ntawm kev siv, cov khoom siv uas tsis tshua muaj nqi yuav tsum raug xaiv kom deb li deb tau.Qhov no tseem ceeb tshwj xeeb tshaj yog rau cov khoom tsim khoom loj.

2) Kev siv cov khoom siv

Thaum qhov tsis zoo ntawm qhov tsis loj thiab qhov kev ua haujlwm loj, tus nqi ua haujlwm yuav suav nrog ntau tus nqi ntawm tag nrho cov nqi.Txawm hais tias cam khwb cia hlau yog pheej yig dua li cov phaj steel, nws kim dua rau vuam cam khwb cia. hlau dua steel phaj rau qee qhov ib los yog me me-ntim lub thawv qhov chaw vim tias tom kawg txuag tus nqi ntawm pwm tsim.

3) Txuag cov ntaub ntawv

Txhawm rau kom txuag tau cov ntaub ntawv, kev kho cua sov lossis kev ua kom muaj zog ntawm qhov chaw (steev peening, dov, thiab lwm yam) tuaj yeem siv los muab kev ua si tag nrho rau thiab siv cov khoom siv hluav taws xob muaj peev xwm; Cov txheej txheem saum npoo (chrome plating, tooj liab plating, blackening, xiav, thiab lwm yam) kuj tuaj yeem siv los txo cov qib ntawm corrosion thiab hnav, ua kom lub neej ua haujlwm ntev ntawm qhov chaw.

4) Kev siv tus nqi ntawm cov ntaub ntawv

Txhawm rau txhim kho kev siv cov khoom siv, tsis muaj kev txiav lossis txiav tsawg dua tuaj yeem siv, xws li tuag forging, peev casting, stamping, thiab lwm yam, uas tuaj yeem tsis tsuas yog txhim kho kev siv cov khoom siv, tab sis kuj txo cov sijhawm ua haujlwm ntawm cov khoom siv. txiav.

5) Txuag cov khoom muaj nqis

Los ntawm kev siv cov qauv kev sib xyaw ua ke, tuaj yeem txuag tau tus nqi ntawm cov khoom siv ntau dua, xws li cov qauv sib xyaw ua ke cab iav nplhaib nrog kev sib txhuam zoo tab sis kim tin bronze, thiab lub log core yog pheej yig cam khwb cia hlau.

6) Txuag cov ntaub ntawv tsis tshua muaj

Hauv qhov kev hwm no, manganese-boron alloy steels nrog ntau cov peev txheej hauv Suav teb tuaj yeem siv los hloov chromium-nickel alloy steels nrog cov peev txheej tsawg, thiab txhuas bronze tuaj yeem siv los hloov cov tin bronze.

7) Cov khoom siv

Hauv kev xaiv cov ntaub ntawv, yuav tsum xaiv cov khoom siv hauv zos thiab yooj yim muab cov ntaub ntawv, txhawm rau txo tus nqi ntawm kev yuav khoom, kev thauj mus los, kev cia khoom; Los ntawm cov khoom siv yooj yim ntau yam ntawm qhov kev xav ntawm kev muab khoom thiab cia, rau cov khoom me me ntawm cov khoom, yuav tsum. txo kom deb li deb tau ntawm tib lub tshuab siv cov khoom siv ntau yam thiab cov lus qhia tshwj xeeb, txhawm rau ua kom yooj yim ntawm cov khoom siv thiab kev tswj hwm, thiab hauv cov txheej txheem ntawm machining thiab kev kho cua sov ntau yooj yim dua rau tus tswv txoj kev lag luam tsim nyog tshaj plaws, yog li txhim kho kev tsim khoom, txo seem, txhim kho kev ua haujlwm tsim khoom.

Post lub sij hawm: Feb-22-2022

- Tom ntej: Cov neeg ua haujlwm nyob

- Yav dhau los: Sekonic Metals Group ntawm Kev Tiv Thaiv Kab Mob thiab Tswj